Electrical Life Test: What It Is and Why It's Crucial for Component Safety

- Amelia Ethan

- Jul 14, 2025

- 2 min read

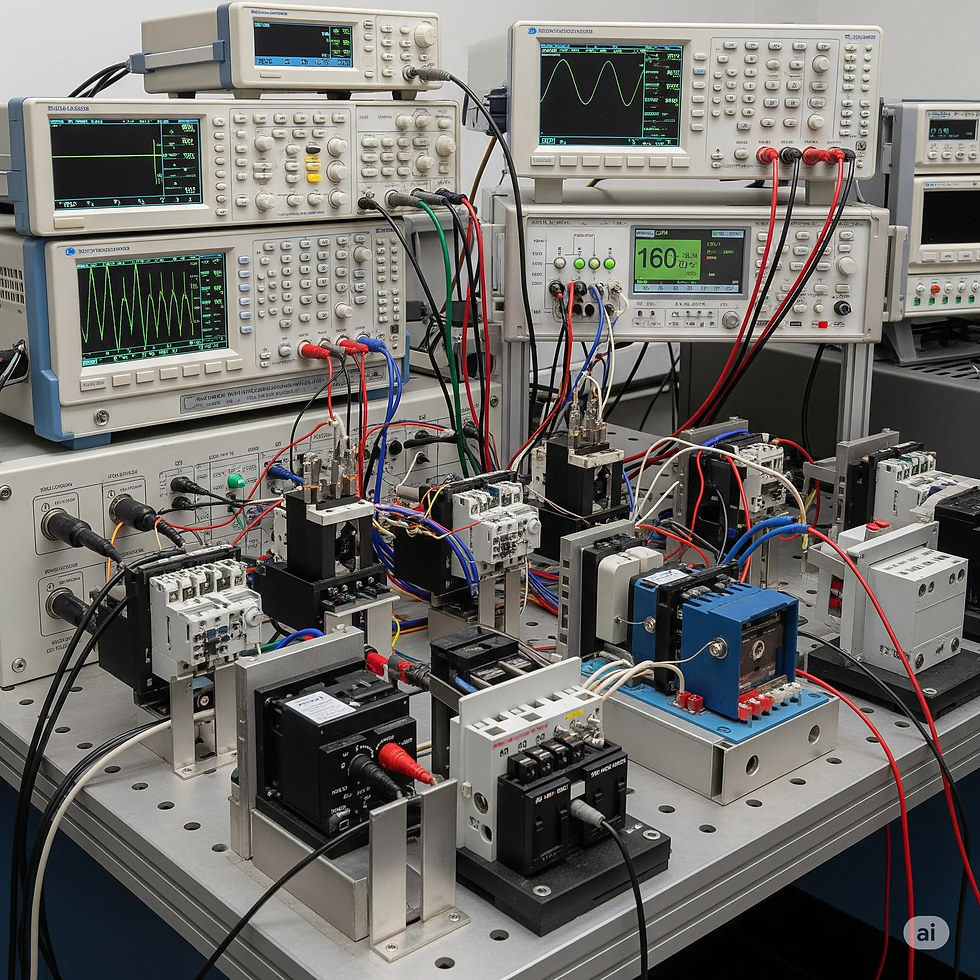

The term electrical life test refers to a series of tests performed on electrical or electronic devices to evaluate their operational lifespan under real or simulated conditions. This test is crucial for ensuring the reliability, safety, and quality of components, especially in high-criticality sectors such as automotive, industrial, aerospace, and medical.

What is an Electrical Life Test?

An electrical life test is a procedure that simulates continuous cycles of operation and electrical stress on a component to determine its useful life. The test is carried out by connecting the device to a power source and replicating the operational conditions it would face over time.

Main Objectives of Electrical Life Testing

Verify the long-term resistance of electrical contacts

Detect signs of wear or material deterioration

Identify premature failures or design flaws

Evaluate compliance with international technical regulations

Components Commonly Subjected to Electrical Life Tests

Electromechanical relays

Switches and buttons

Electrical connectors

Printed Circuit Boards (PCBs)

Electronic sensors

How an Electrical Life Test is Performed

Device Preparation: The component is installed on a test bench with all necessary connections.

Simulated Electrical Cycles: Continuous or alternating current pulses are sent at pre-established intervals.

Parameter Monitoring: Voltage, current, temperature, and contact resistance are recorded.

Final Analysis: After a defined number of cycles (e.g., 10,000), the component's functional integrity is assessed.

Factors Influencing Electrical Lifespan

Type of conductive material

Activation frequency

Applied current and voltage levels

Environmental conditions (humidity, temperature, vibrations)

Quality of internal design

Advantages of Performing an Electrical Life Test

✅ Prevents failures in real-world conditions

✅ Increases customer confidence in the product

✅ Makes it possible to obtain quality certifications

✅ Reduces post-sale repair costs

✅ Assists in selecting the best suppliers

Reference Regulations and Standards

Test execution may be regulated by international standards such as:

IEC 60068 (environmental testing)

MIL-STD-202 (military standards for electronic components)

UL and CE for safety certification

Conclusion

The electrical life test is a fundamental tool for evaluating the quality and reliability of electrical components over time. Performing electrical life tests rigorously and controllably reduces risks, improves design, and ensures products that last, even under the most extreme conditions.

Comments